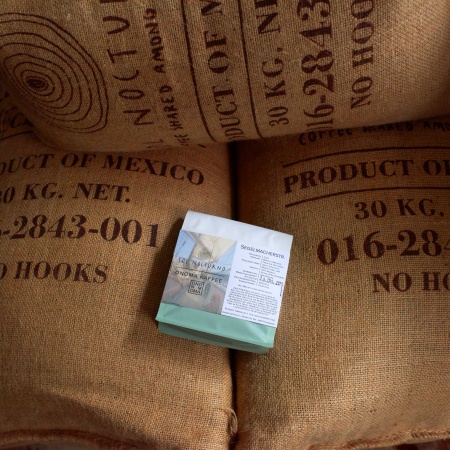

Decaf Project by James Hoffmann

Last batches we held for shipping problems, etc.

Roast date 01.12.2024 - half the price.

4 x 55g of coffee

1 x 55g unprocessed

1 x 55g Swiss Water Decaf

1 x 55g Sugar Cane Decaf (Etyhl Acetate)

1 x 55g CO² Decaf

Origin: Colombia, Huila, Guadalupe

Producer: Farmers of Guadalupe

Elavation: 1,200 - 2,000 masl

Variety: Caturra, Colombia, Castillo

Process: Washed

FOB: 3,65 $/lb / 7,41 €/kg

Price we paid: 12,00 $/kg / 11,05 €/kg

Further prices for decaffeination are requested and will be updated once received.

Importer: Caravela Coffee

Godfather: James Alexander Hoffmann

We roasted these coffees so that their unique flavours would differentiate them from one another. All these are filter-focused roast profiles.

Dieser Artikel ist leider im Moment ausverkauft!

Attention: This is a pre-order. Once added to an order the whole order will not be shipped before the 5th of December!

Obacht: Dieses ist ein Vorbestellartikel. Bestellung in denen das Set enthalten ist, werden grundsätzlich nicht vor dem 05.12. verschickt!

About the Project

The Decaf Project, spearheaded by James Hoffmann, is an exciting initiative that showcases three distinct decaffeination methods alongside a non-decaf option, all crafted from the same exceptional coffee lot. Do not miss this opportunity to explore the intricate world of decaffeinated coffee and see how different methods impact the final cup. Whether you are a coffee connoisseur or simply curious, this set is perfect for tasting the innovation behind decaf while celebrating the tradition and dedication of the coffee farmers of Guadalupe, Huila.

The coffee selected

La Virgen, cultivated in the highlands of Guadalupe, Huila, Colombia—a region known for its rich coffee-growing heritage is the coffee that was selected for this project.The dedicated coffee families of Guadalupe have cultivated their craft through generations, producing high-quality coffee with a deep commitment to environmental sustainability. With farms averaging 5 hectares, many of these growers have achieved Rainforest Certification and are fully compliant with EUDR standards, ensuring responsible farming practices that protect their environment and communities.For the Decaf Project we divided one special lot of La Virgen into four parts—three were decaffeinated by our partners using different methods, and one remains as unprocessed washed coffee.

Contributing Producers

Coffee growers in Guadalupe are very traditional coffee growers.

They work with their families and their communities to grow and produce coffee how they’ve learned through their lives from their parents and grandparents. Additionally, coffee growers in this region are very committed to the environment, some of them having achieved the Rainforest Certification.

Each farm has their own wet mill and drying infrastructure or at least one per family in which they all share their spaces. They own farms with average of 5 hectares. In the last few years, we’ve noticed an interest in improving their quality, changing some varieties and processes with the objective of achieving better quality for their coffee.

In Guadalupe, we work with many aging producers. However, many of the sons and daughters of these producers are stepping up to support and continue with the family traditions with greater energy, innovation and care for the environment.

Swiss Water Decaffeination

First, green coffee is soaked in fresh hot water, which allows the soluble solids to “leech out” of the coffee. Once the solids are all dissolved into the water the coffee is then removed and disposed of. The third and final step in making Green Coffee Extract (GCE), is to take the solution and filter it with the proprietary carbon filter. The brilliant thing with the carbon filters is that they remove only the caffeine and nothing else, all the green coffee solids remain in the water. We then have the GCE solution. It’s important to note that the GCE is what you would refer to as a “living liquid”. Whilst the decaffeination is taking place the GCE gets refreshed and renewed by the carbon filters.

Next, the caffeine-free GCE is introduced to green coffee. When this happens, the caffeine is transferred from the bean to the GCE; this is called diffusion and is the result of caffeine imbalance. As the CGE is saturated with "flavour" the green coffees flavour compounds are left untouched.

After roughly ten hours, when the coffee is 99.9% caffeine free, the green beans are sent to the dryer. After the decaffeinated beans have been removed, the GCE is now saturated in caffeine from the coffee and is therefore sent to carbon filtration which traps the carbon molecules. After filtration the CGE is monitored and can be used again.

Ethyl acetate (EA) Decaffeination

Ethyl acetate is a natural component of sugar cane, coffee, and fruits such as musk, strawberries and bananas, but is also produced synthetically. It is also used as a natural or artificial flavouring in food products.

Ethyl acetate is used in decaffeination because it is highly selective with respect to caffeine and can physically extract it from green coffee beans in a gentle, but targeted manner. To do so, the green coffee beans are first treated with steam to remove the silver skins. The water content of the beans is increased to open up the cell structure. Then the water-ethyl acetate-solution is used to selectively extract the caffeine from the beans in several steps, where the caffeine diffuses from the beans into the solvent-water-solution around it. Subsequently, steam is used to remove the remaining ethyl acetate from the beans, which are finally dried to their initial moisture content.

Subcritical CO² Decaffeination

The green coffee is first placed in a vat and treated with steam. This step is a prerequisite for decaffeination, and prepares the coffee beans by swelling them to make them more permeable for extraction with liquid CO².

The beans are then brought into contact with liquid CO² under subcritical conditions. During extraction, the liquid CO² continuously extracts the caffeine from the coffee beans. The caffeine is then dissolved in the liquid CO². Because CO² has a very high selectivity for caffeine, virtually no other components are dissolved, resulting in very high quality.

The flow of liquid CO² then transports the caffeine into a separate tank, where the CO² is evaporated back into a gaseous state. As a result, the CO² loses its affinity for the caffeine. The purified CO² is then converted back to a liquid state (by compression) and returned to the decaffeination tank to begin a new cycle.

Finally, once a caffeine content of less than 0.08% has been reached (European regulations impose a maximum caffeine content of 0.1% for decaffeinated coffees), the beans are taken out and dried under vacuum and mechanical drying.

Zurück zur Übersicht